Collision Repair

Stainless Steel Wet Mix Dust Collector w/ Low Water Auto Shut Down

USD $9,602.00

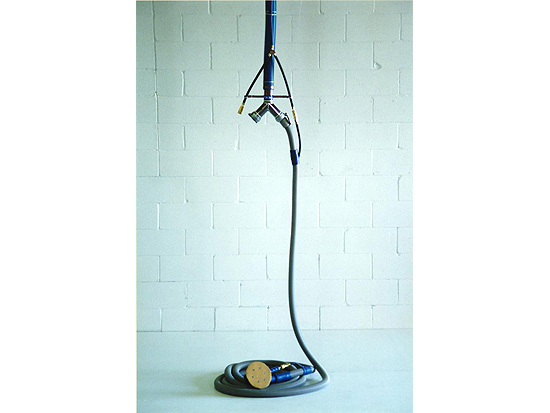

Eurovac II - 2.5HP Stainless Steel Wet Mix Dust Collector (Capable of 2 Orbital Sander User System) Includes: Qty. 2 - 25' Hoses with airline & hose/tool hangers.

How the unit works:

Explosive dust is drawn into the unit through and forced down through a venturi, deep into the water. The water acts as a separator, and the majority of the dust particles fall to the bottom of the unit immediately. Those particles that manage to escape this first stage of cleansing, are forced through thick curtains of water, and are deflected by a series or baffles into the water turbulence, separating the remaining dust from the air. The moist clean air is drawn through the unit by an internally fitted blower, passes through a stainless steel mist eliminator, where the moisture is removed from the clean air. The dust which has settled to the bottom of the unit is removed through the sludge drain valve.

The Eurovac II Wet Mix Dust Collector has a powerful 2.5HP 1440 watt motor that enough suction for two technicians to sand at the same time.

Features

- Wet mix dust collector, fabricated from 14 gauge stainless steel which is then thermo set powder coat painted.

- Manual water level system whereby the customer fills the unit with more water when the water level gets to a certain level marked on the site glass.

- Manual drain valve located at the bottom of the separator.

- Initial stainless steel venturi entry for deep penetration into the water, secondary baffles to completely mix the dust particulate with the water whereby no after dry/hepa filter is required.

- Site glass to visually check the water level.

- Relief valve set for exhausting hydrogen gas build-up in an aluminum application.

- Automatic low water shut down sensor which prevents the unit from operating if water is not set at proper levels.

- A time delay switch is provided to prevent the start of the dust-producing process (sanding tools) until the collector is in complete operation.

- An off delay time switch is provided which allows the system to run for a set amount of time once the sanding has stopped. This ensures all dust in the hose reaches the collector.

- 2" ball valve & hose at the bottom of the separator for removing sludge

- Compliance with NFPA Code 484 - 2015 (Standard For Combustible Metals) System Uses: Source capture hand tools for aluminum dust.